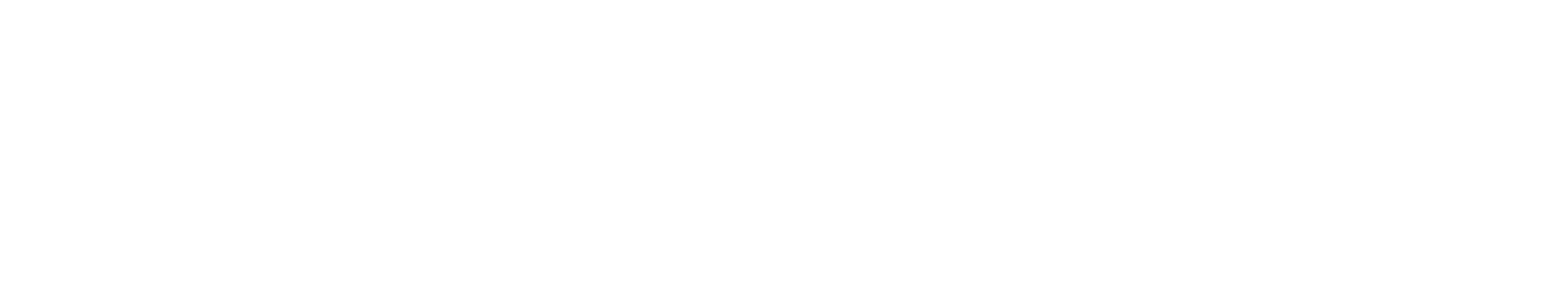

For my Final Major Project, I explored the impact of sustainable resources while incorporating the use of produce supplied by the local businesses of Farnham. As a company British Wool collect, grade, market and sell wool on behalf of their producers to the international wool textile industry. Their aim is to “create a quality mark, recognised by consumers for superior product performance while creating a fairer deal for producers”. The Monks’ Dorter, a ruin which forms part of the Waverley Abbey site was originally a space where the monks, priors and abbots ate, prayed and slept as part of their culture. This building will be adapted to provide Farnham with a fabric dyeing facility, aiming to promote sustainability. Aiming to appeal to the younger generation, the facility will provide workshops aimed at families where they will partake in learning the natural dye process before participating in dyeing sustainably sourced fabrics.

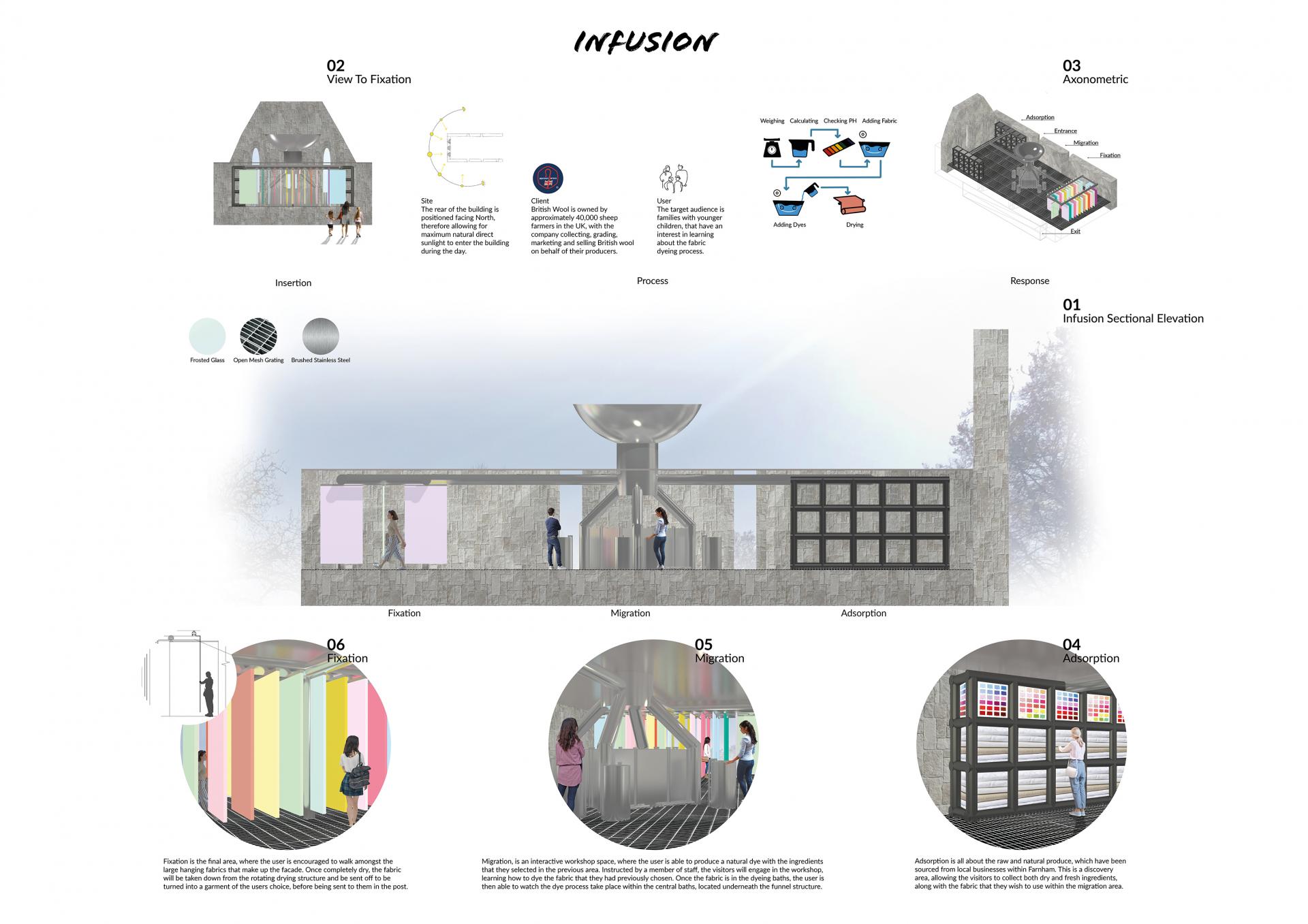

Titled infusion, I was inspired by the five stages of the fabric dying process which influenced the insertion into the building using models, sketches and CAD to create a free stand structure. This is influence by the form of a funnel located in the centre of the Monks’ Dorter, supported by large structural framework that extends throughout the building and incorporates both shelving units to house the materials as well as a rotating fabric drying unit.

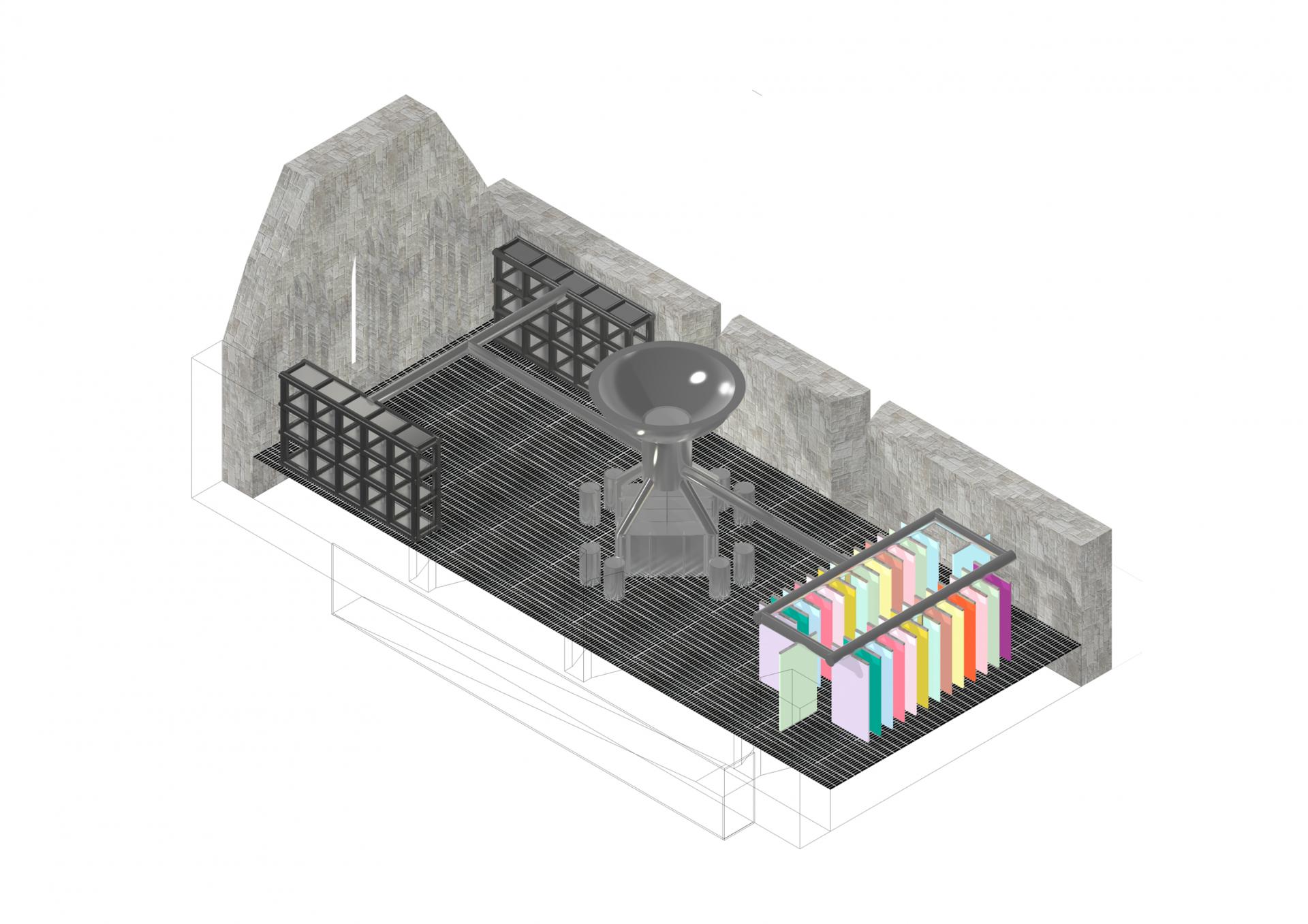

Within the production of natural dyes an understanding of the ingredients is an important of the process, along with knowledge of the material that is being dyed, ensuring high quality products. The scheme utilizes sustainable resources with a central funnel being used to collect rainwater, which is then used during the fabric dyeing process. Once the fabric has been dyed it is then hung to dry with the assistance of both the sun and the wind. This approach will use locally sourced fabric and produce for the dyes, which is displayed on stainless steel storage units. The produce is stored within a selection of different sized and shaped storage containers allowing the user easy access to the resources. As part of the drying process a pulley system rotates the fabrics, creating the colourful and changing façade of the building.

Overall, the scheme incorporates the use of sustainable resources and produce supplied by business in the local area, to produce high quality products while promoting sustainability towards the younger generation.